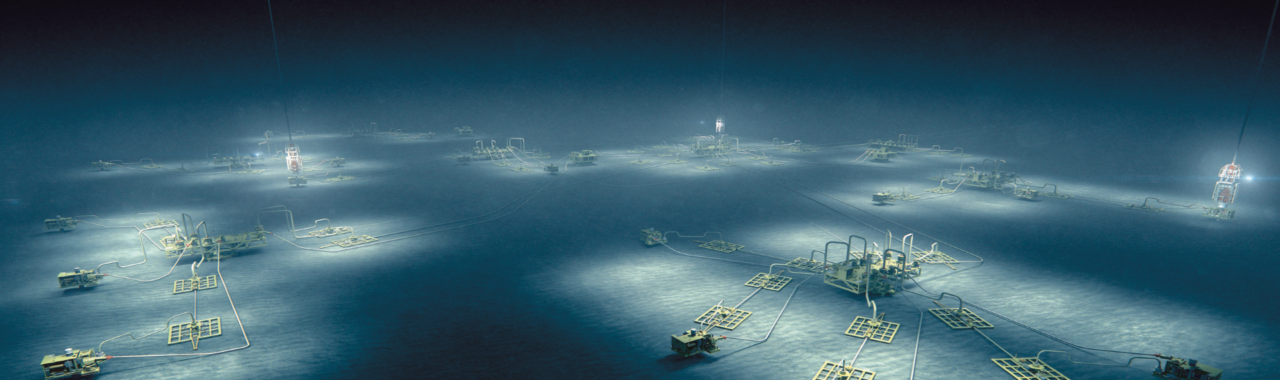

Aker Solutions and Seabed Separation A/S Cooperate on New Subsea Concept

Aker Solutions and Seabed Separation A/S has entered a technology cooperation agreement promoting a new subsea separation concept.

The new concept named “The Dual Pipe Separator” (DPS) solves the challenges of high-cost field development, increasing water production and higher Environmental Sustainability Goals (ESG) requirements.

Aker Solutions and Seabed Separation A/S have agreed to promote this technology together to the market for field applications.

Subsea separation using the DPS system will give less backpressure to the reservoir, thereby giving higher production and recovery.

“Adding the Dual Pipe Separator solution to the low carbon toolbox, gives us even more alternatives to increase the recovery factor on a field development for our clients,“ said Morten R. Pedersen, Senior Vice President of Subsea Engineering at Aker Solutions.

Benefits of this new compact system include reduced use of materials, lower energy consumption, in addition to lower CO2 emissions. In comparison, the lifecycle CO2 footprint is much lower than for conventional platform topsides. The DPS components are qualified and approved and now available for the market.

“Joining forces with Aker Solutions to promote subsea separation as a tool for the oil companies, strengthens our efforts to meet the ESG and EOR. These are issues I am personally committed to finding solutions to, and that I’m looking forward to work with,” said Jon Berntsen, chief executive officer of Seabed Separation.

The DPS system consists of a modularized unit with inclined pipe separators that will give a stable flow and separation process, and increased oil recovery.

The DPS system is an enabler for efficient and profitable development of subsea fields and can be applied in deep water up to 3000m with a shut-in pressure of 350bar. The DPS will increase the recovery from your field and optimize capex exposure, profit, and risk. The solution is deployable for both greenfield and brownfield applications.

Dual Pipe Separator (DPS) – How it works:

- The well stream enters the gas harp which suppresses incoming energy and splits the liquids and gas. Gas being transported to DPS oil outlet and commingled

- The liquids, without free gas, having low velocity, less than 1.5 m/s enter the horizontal 6 pipe and forms two-layer flow, oil on top and water below

- The two-layered flow enters the tilted Dual Pipe Separator inner pipe. The inner pipe expands from 6 to 18 hence further reduces the velocity and the oil is, through large holes, guided out in the top and the water is guided to the lower part through similar perforation

- The oil phase leaves the top of the DPS, meets the gas and further transported in the downstream pipeline

- The clean water is removed for further treatment or reinjected.

- Inside the DPS an interphase controller monitors and maintain the correct water level

- No moving parts. No valves. No internals