The DPS technology is protected by three patent families, where two have been awarded US patents (US Patent 9,724,623 and US Patent 9,827,509) and EU patents, and one has been awarded a Norwegian patent NO Patent 341580. The technology behind these patent families have enabled a large number of capabilities in the market place.

Re-use of equipment modules and produced water management system on new locations

- The DPS system can together with the rest of a produced water management system, due to its low weight, be recovered from a site, revamped and re-used at a new location.This reduces the Capex requirements significantly

- We can enable a SPSO service model (Subsea Processing & Storage Operation)?

FEATURES

-

Reduce OPEX

-

Reduce CAPEX

-

Increase productivity

-

Enhance flow

-

Business opportunity

Efficient topside debottlenecking of the produced water management system

- A low weight and small footprint solution for topside retrofits

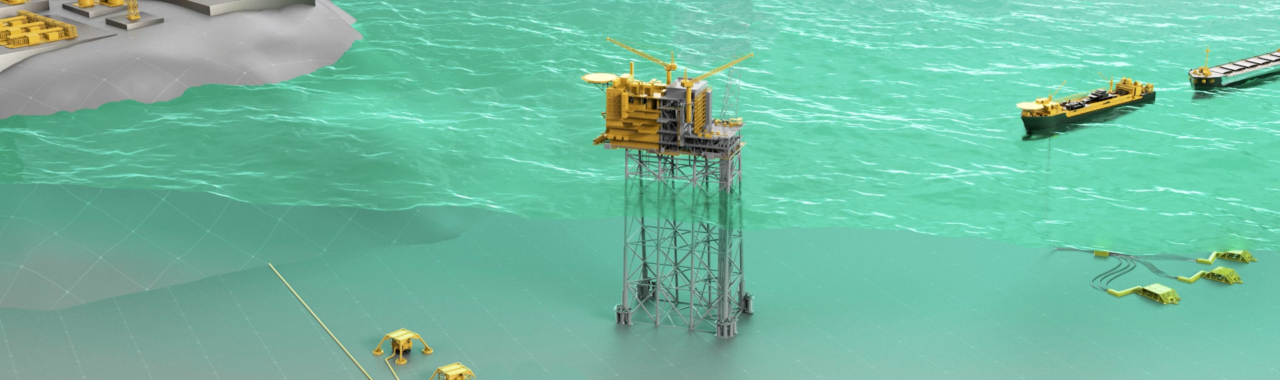

- Our DPS System can easily be installed topside a platform or FPSO, providing extra water processing capacity and a slug management system

- By increasing the overall liquid handling capacity of the topside, and also improve the overall process performance of the facility by effectively removing the water early in the process (upstream of separators)

- Weighing less than 1/3 of a conventional separator system

Production with significant reduction in chemical usage and improved environmental impact factor.

- Removing the produced water close to the source and before the fluids have been exposed to any major pressure drop, will drastically reduce the need for chemicals. Both for transportation and corrosion inhibition in the pipelines, and later in the final topside processing of the oil. The oil will also have a higher export quality without all the chemical residues

FEATURES

-

Debottlenecking

-

Lower water cut

-

Reduce cost

-

New business development

-

Increase revenue

Enables debottlenecking of existing asset infrastructure to achieve improvements

- The DPS can be a major tool to debottleneck a larger asset area

- By using the DPS as an asset area business optimiser you can achieve a whole network of positive effects. Removing the water at the source will open up extra capacity for oil production from existing and new field, improve reservoir performance and optimise the topside facility to focus on a lower water cut

- The DPS will enable area debottlenecking to reduce cost and increase revenues, and at the same time open up for new business development to fill up the newly made available capacity

Increased production through accelerated production of new wells / satellite fields using existing infrastructure

- Enables accelerated production of existing, and start-up of new fields by opening up extra pipeline capacity

- By removing the water from the pipeline, the existing infrastructure can be used to transport new oil and gas volumes instead of today’s situation where new fields have to wait in line or produce at reduced capacity

FEATURES

-

Low energy consumption

-

Pump-free boosting

-

Reduced back pressure

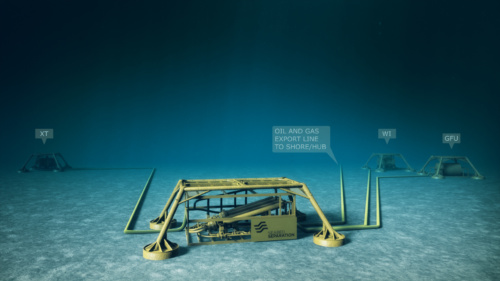

Increased production from increased oil recovery (lower back pressure) with minimum energy required

- Pump-free subsea boosting – The removal of produced water at the seabed has similar effect to a subsea booster pump, with increasing effect as a function of increased water depth and water cut. The DPS could in some cases effectively boost production by 25-30 %

- The effect comes from the reduced back pressure on the reservoir since the water is separated away from the oil and thus not lifted to topside. (hence an improved recovery factor when the reservoir has some extra pressure to work with.)

- The reduced back pressure at the wellhead implies lower pressure downhole in the reservoir section. As production is driven by the differential pressure, the reservoir rock volume affected by the well increases when bottom-hole pressure is reduced. The larger rock volume exposed to drawdown from the well, the higher the production and overall recovery