How do we handle issues with sand and debris in the process stream coming from the reservoir?

Introduction

Sand and debris will most likely come as a part of producing the wells from an oil reservoir. The sand and debris issues will occur during transient flow conditions like during start-up and shut down of wells, malfunction of sand screens or packers downhole, or as finer silt particles following the well fluids.

In a perfect world sand issues should be handled elsewhere in a hydrocarbon system, but we have to cater for this in our separation system and in collaboration with the other system providers on an integrated subsea processing and production template.

We have designed our system such that sand, debris and finer particles should not be an issue in our overall processing performance.

Where will sand and debris most likely be an issue and how do we handle it?

We have during our system development and performance verification, now at TRL4, conducted several flow assurance studies to evaluate where we might have issues with accumulation of sand and finer particles, and designed our inclined Dual Pipe Separator (DPS) to ensure we do not under any circumstances will see any accumulation of solids in the system.

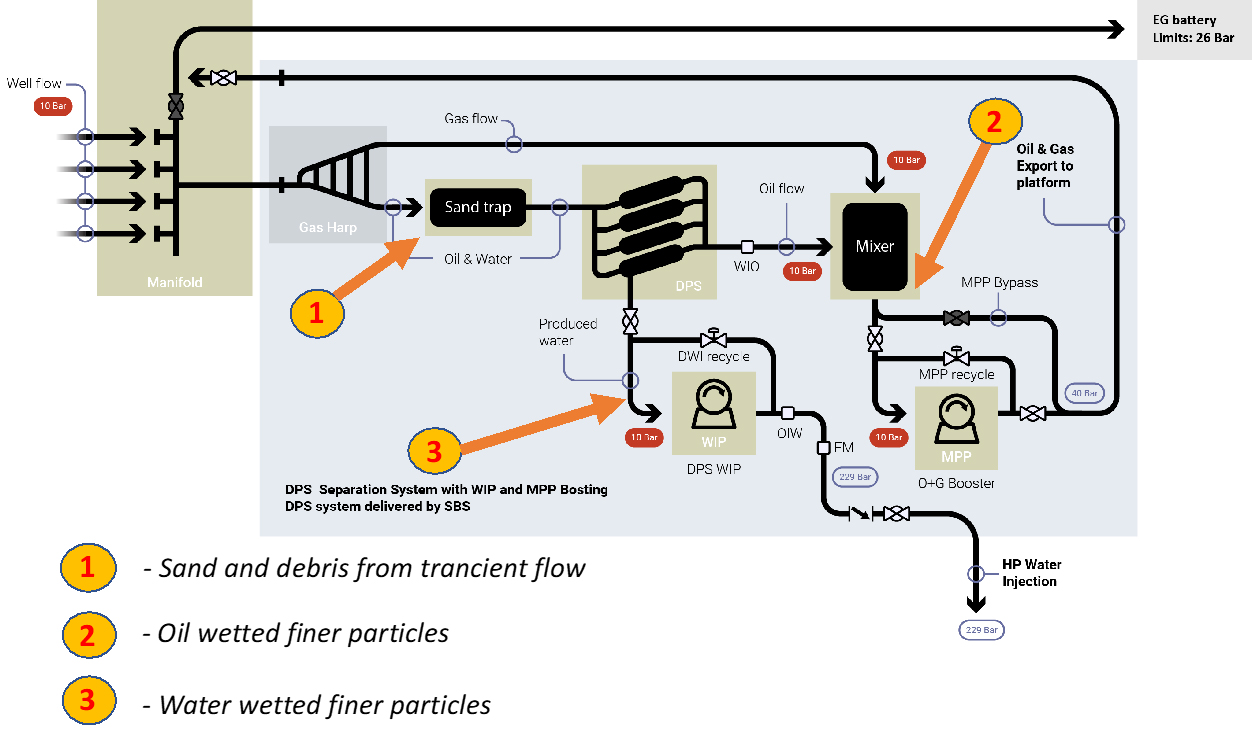

However, when we look at an overall subsea processing and production system (see figure 1), there might be issues during the lifetime of wells and a subsea system should be designed to cater for these issues. During discussions with our integration partners and customers we have narrowed it down to; (1) sand and debris early in the process, (2) finer particles in the oil phase, and (3) finer particles in the water phase. See figure 2 below for an indication of where the issues might be handled.

Sand and debris from transient flow is managed and collected prior to the separator of oil and water(1):

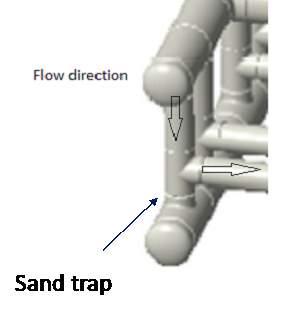

The sand and debris from transient flow conditions are collected in the Conditioning Pipe section of our system and upstream of the header for the DPS separator units. The sand trap we propose to use here is based in a well proven gravity principle combined with a change of flow direction (See figure 3). The sand and debris are thus removed from the liquid flow and collected in a separate sand compartment located at the bottom of the subsea structure.

The sand can be removed from the system using ROV for;

– flushing and suction into a dedicated ROV basket, or

– changing out and collecting the sand compartment to surface for cleaning and replacing it with a new compartment

The sand trap is positioned in Conditioning Pipe section between the Gas Harp and the DPS units, where we have a maximum flow velocity of 1,5 m/s. The controlled liquid flow regime we establish here is ideal for catching the sand and debris.

We have designed our system with a pig loop in the basement to enable bypass of our system during pigging operations. This could of course also apply to specific operations with a large amount of sand and debris.

Oil wetted finer particles follow the oil flow (2):

We have found that based on a larger number of installations, topside and subsea, that the oil wetted fines do not fall out in the 1st stage of separation, but more so in the 2nd stage and mostly in the stabilization stage (3rd). We therefore anticipate that the oil wetted fines will be transported in the oil home to a central processing facility. The MPP pump system will need to be design for these fines. We foresee no oil wetted particles will accumulate inside any parts of our system.

Water wetted finer particles can be filtered out (3):

During the later stages of a reservoir there might be more water wetted finer particles and these will be handled when the water is re-injected into the reservoir. The remedy might be some form of. A filtering station with back flushing cleaning mechanism. The backflush flow can then be spiked into the oil and gas for transport and separation at the central processing facility. The filtering station will be position after the DPS System and before the water injection pump(s).

Conclusion

The issue of sand production will be the same for all SPS and subsea systems and so also for our DPS System. Compensating measures must be designing in for the subsea systems to work effectively. The sand management philosophy is decided by the operator and integrator and our DPS System will integrate into the Sand Management Systems.