How do we handle issues with wax and hydrates in the process stream coming from the reservoir?

Introduction

This memo addresses the potential issues related to wax and hydrate occurring in hydrocarbon production system. Issues related to wax and hydrates will most likely be relevant during process shut down periods. The DPS system is normally located close to the production template and will during normal operation operate at elevated temperatures. During that condition, any wax precipitation will hardly occur and issues with hydrates is not possible since the DPS has no pressure drop.

The only possible condition in which a wax generation or a hydrate formation situation might occur is during a shutdown of the production. Stop in production can be a planned shut down or an unexpected shut down. Since the DPS system is positioned on the seabed and therefore in a cold external environment the system temperature will drop and move close to ambient temperature.

Will the cold situation cause any significant problem to the DPS system?

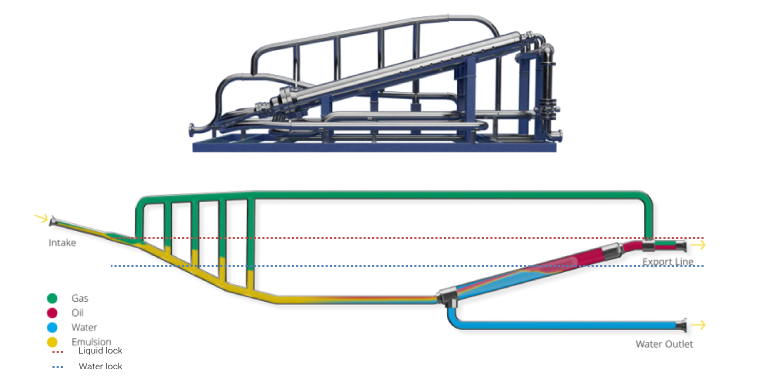

The illustration (figure 1) below show the accumulation of liquids when the flow stops. Since the DPS system is designed as a “low point” in the fluid transport system the water will accumulate at the bottom, below the water lock blue dotted line, and the oil will accumulate below the red dotted liquid lock line, on top of the water.

Figure 1. An illustration of the DPS system

Hydrate issue:

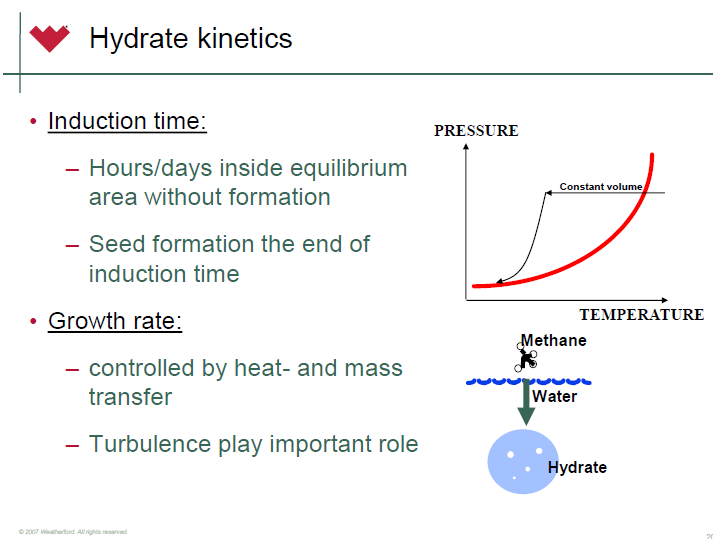

– It is generally known that to generate hydrate formation it requires continually flow of gas that is saturated with water vapor in combination with low temperature.

– If the water contains NaCI the process of generating hydrates will be reduced. In an oil field the produced water contains typically high volumes of salt.

– A prerequisite in creating hydrates is the reduction in temperature. In many cases this is typically induced due to small local pressure drops. The DPS system is under all kind of operations not exposed to any pressure drops.

– If the gas and the water is isolated from each other during a shut down, the risk of hydrate generation is reduced.

As seen on figure 1 the design of the DPS system will have an upper part, green color, that contain gas. Furthermore, it is important to observe that the water is prohibited from direct contact with the gas due to the oil in place between the liquid lock and the water lock. During a shut down in flow, any water in the gas section (gas harp) will be drained into the water section, hence avoid generation of hydrate crystals in the gas harp.

It is known that generation of hydrates are influenced by temperature reduction often related to local pressure drop (Joule-Thomson effect) . This will never happen in the DPS system since hardly any pressure drop is possible.

Wax issue:

The location of the DPS system close to the production template and the process temperature is therefore normally high. During such normal process conditions, it is unlikely that wax build up will happen.

During a process shut down the flow will stop and with time the fluid temperature will drop down towards ambient temperature. The precipitation of wax crystals might occur in small volumes and locally, but the accumulation required to cause clogging of the entire DPS system, or individual DPS pipe is not possible without liquid flow. During a shut down there is no flow and thus no build-up of significant wax levels. Soon after a start in flow, the wax will melt and disappear.

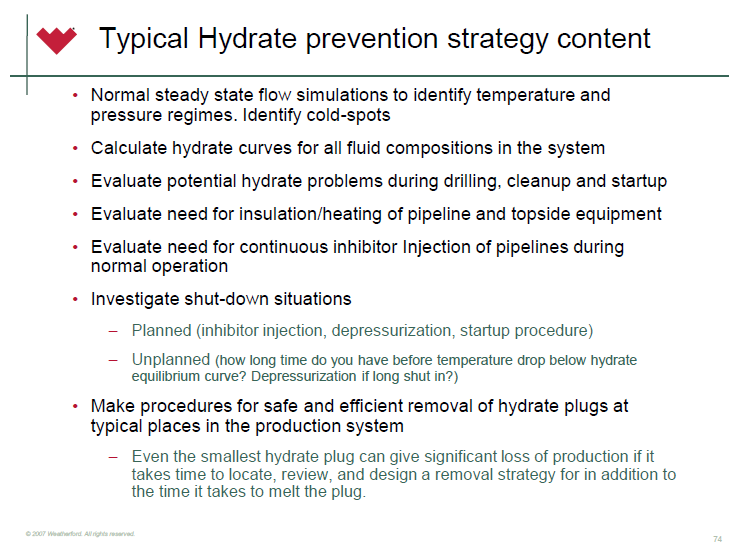

How will we handle the issue of wax and hydrate management (Figure 3) below highlight some of the more common approaches to managing the issues of wax and hydrate management and how to mitigate this from becoming an issue, both from design around the issue and using particular operational modes to compensate.

Our approach is that all the issues of wax and hydrate management should be defined specifically for each project and included and solved in the design studies leading up to a detail design of a subsea production system where our DPS system is an integral part. Our initial thoughts are that we will have no extra requirement for special design or operational procedures compared to the overall subsea production system.

Conclusion

The issue of wax and hydrates is not rated as a big issue with the DPS system due to location, design, and way of operation. The DPS system is designed to follow the normal procedure as the pipeline during planned shutdown periods. Inhibition being the typical method. During the FEED phase all aspects related to wax and hydrate will be addressed i.e. following the method described in figure 3.