Seabed Separation shows an IOR case

Introduction

This business case is based on a selection of business cases Seabed Separation have performed for partners on the Norwegian Continental Shelf (NCS) and as such represents a typical subsea tie-back arrangement to a central processing hub.

The main benefit will be from our ability to take away the water at the seabed which again reduces the back pressure on the reservoir and results in Increased Oil Recovery (IOR). The water is released to sea or re-injected to the reservoir using a water injection pump (WIP). The IOR effect is further improved by adding multiphase boosting pump(s) (MPP) on the subsea installation.

Finally, we have also included the capability of being able to perform individual well testing at the same time as we maintain the overall production from the other wells.

The IOR effect is thus from both improved reservoir performance and reduction of lost production during well testing operations.

How do we do it?

We have developed an “IOR Machine” comprising of our patented Dual Pipe Separator (DPS) system, a water injection pump and a multiphase boosting pump. The IOR Machine will give quick IOR effects by drawing down the operational pressure on the seabed. See figure 1.

Combined flow assurance studies and reservoir modelling have given us the insight into how reservoirs typically reach when we install and operate the IOR Machine. We have seen between 10 – 20 % IOR improvement on the overall remaining production, and in addition we have seen that the effect is skewed towards the first 3-4 year after installing the IOR Machine. This is even more financially inspiring.

We typically install the IOR Machine immediately downstream of the production wells, either as a retrofit on a brownfield or as a part of a greenfield tie-back.

Business Case

Background:

The “synthetic” field in this business case have the following characteristics;

– 60 000 bbls/d initial oil production

– We reduced the operation pressure from 70 to 20 bar at the seafloor (the lowest possible operation pressure is most often determined by the GLR (Gas Liquid Ratio) capability of the MPP, or the gas velocity in the existing subsea infrastructure)

– The water depth is 400+ meters

– The subsea template is set up with 4 producing wells

– One water injection well in the area

– Multiphase boosting added

– 10 years projection for the IOR case and extension of production life is anticipated

– IOR Machine retrofitted and operational mid year 3 of production

Production improvement:

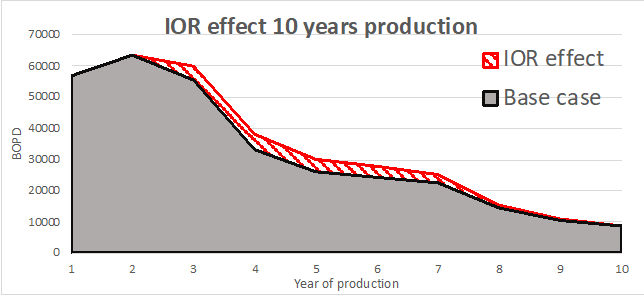

The IOR effect over the next 10 years is plotted in figure 2 below and illustrate how the IOR effect from the reduced back pressure on the reservoir will pan out.

The overall IOR effect for the period represents an increase of 9,6 % in total oil and represents a revenue increase close to 400 Mill USD million over the entire period (50 USD/B and 10 NOK/USD).

Reduction of Lost Production:

Our test functionality enables simultaneous testing and production, i.e. no production loss.

The assumption is that every well need two test periods of 24 hours every year for the duration of the field life. During all these test periods the other three wells should have been shut down. This result in the following annual improvement:

( ( 3 wells x 2 day) / 365 days ) = 1,64 % annual improvement and represent approx. 65 MUSD over the entire period.

Overall financials:

With a Capex requirement of 80 – 100 MUSD for an IOR Machine for this application combined with the benefits from the IOR and the reduction of Lost Production, the NPV 10 % (Net Present Value) would be in the order of 40-60 MUSD.

The volume of gas (in oil equivalents) is not included in this IOR calculation since gas volumes varies very much from reservoir to reservoir. Some reservoirs have proved to provide a significant NPV contribution from the gas.

Conclusion

The Dual Pipe Separator as a central part of the IOR Machine will in most cases prove to be a very profitable investment for most operators. The combination of test functionality and IOR capability is an enabler for better development of new fields and redevelopment of old fields.

The economics for new tie-back field developments are even more appealing since most of the topside brownfield scope on the central processing facility can be excluded from the overall scope.