For an operator the key thing is to optimise the financial benefit from developing an oil & gas field. By phasing the development over the life of the field the operator will not only ensure optimum use of production solutions but also the financial benefit. For subsea development projects, tie-backs and larger standalone projects, our Dual Pipe Separator will be a crucial part of such a subsea development solution. Combined with financial engineering through leasing the NPV will also be improved.

The phased development approach

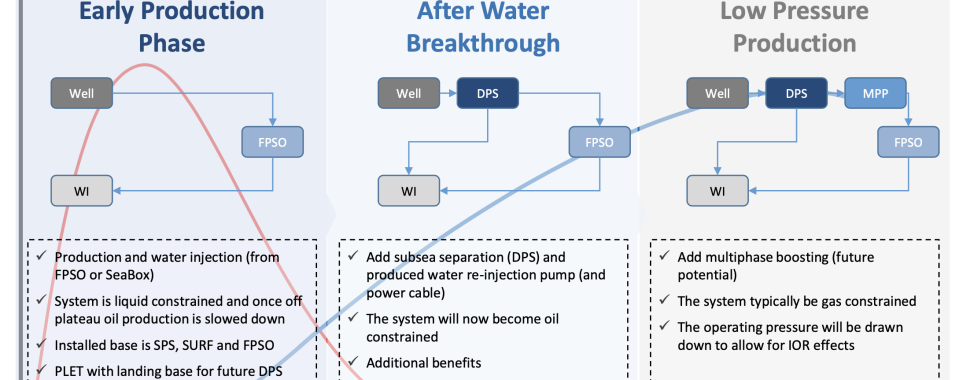

In a phased subsea field development we would typically look at the three main phases of an oil & gas field; (1) Initial plateau, (2) after water breakthrough and finally (3) the low pressure production phase, all described in more detail below.

- The plateau and early production phase – here the operator only needs wellhead systems, pipelines, control systems and risers, and in most cases a pressure support system like water re-injection, and to provide some additional flexibility for the future phases by adding subsea connection tees.

- The water breakthrough and increased water cut phase – here the operator needs a subsea separation system to separate out the production water and thus the dry oil & gas will be exported back to the central hub. Here’s where our Dual Pipe Separator (DPS) System comes to play. The DPS would enable Increased Oil Recovery (IOR) through removing the water column in the riser and thus the back pressure on the reservoir. The cleaned water can be reinfected back into the reservoir together with the clean seawater.

- The low pressure and boosting phase – if the reservoir characteristics allows for it, low pressure production might follow with a need for multiphase boosting of the oil & gas. This will be the ultimate effort to achieve IOR benefits.

Development approach to match

The phased development approach allows for bringing in the optimum subsea production solution when you need it, and not all up front. This is both a more financially sound solution and a more technically smart solution, since the field characteristics might change over time and the phased solution allows for optimisation to be build in all the way up to subsea installation of the next phase.

Phase 1 would see the overall production system being installed, with support for the future installation of subsea separation and possibly multiphase boosting. This could typically mean installing a substructure with well template and space for the future DPS system, or even simpler, a subsea tee arrangement for future tie in. A system for reservoir pressure maintenance like the SeaBox could be applied here.

Phase 2 would see the DPS System being installed after the water breakthrough have occurred, and the system would piggy back on the already installed service umbilical(s) for instrument power, subsea controls and communication to the central hub. A medium additional power requirement for the water reinfection pump would be required. The 2nd phase will also give the operator opportunity to evaluate whether the field is also a candidate for phase 3 and multiphase boosting.

Why is leasing more advantageous here?

Large parts of the subsea production system for the Phased Field Development approach can be refurbished and reused on other new field development project. The subsea production system has therefore a residual value after the first project, and the leasing structure will be more advantageous to the end client compared to a pure Capex element.

New business model enables – Subsea Production as a Service

This might be an opportunity for replicating or even extending the current FPSO business model in the oil & gas industry!