< 0 ppm

Oil in Water quality

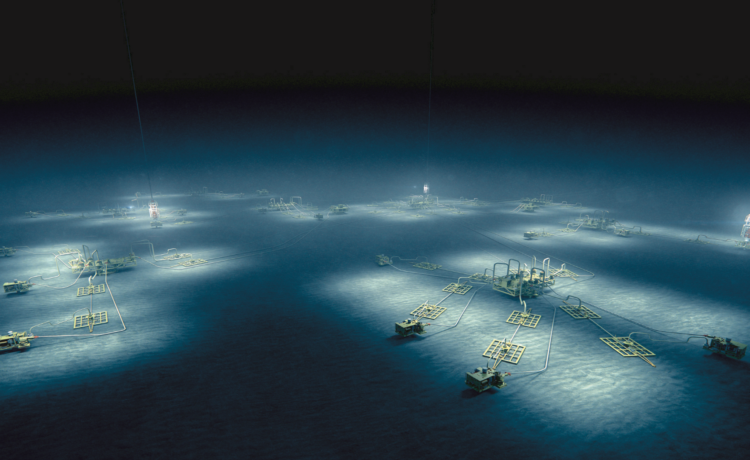

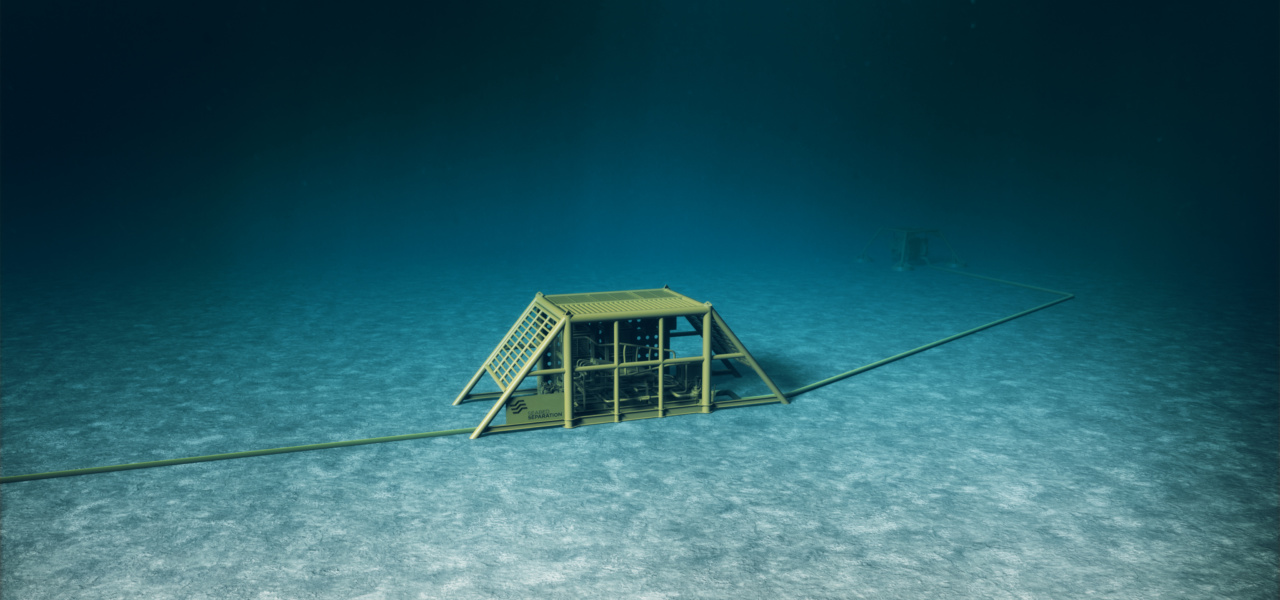

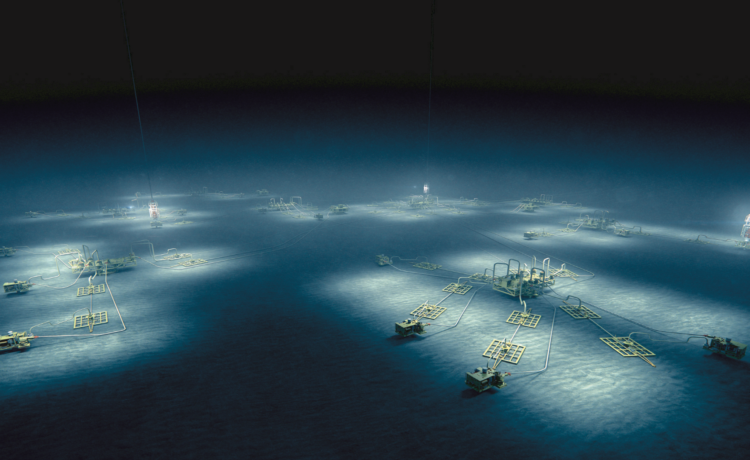

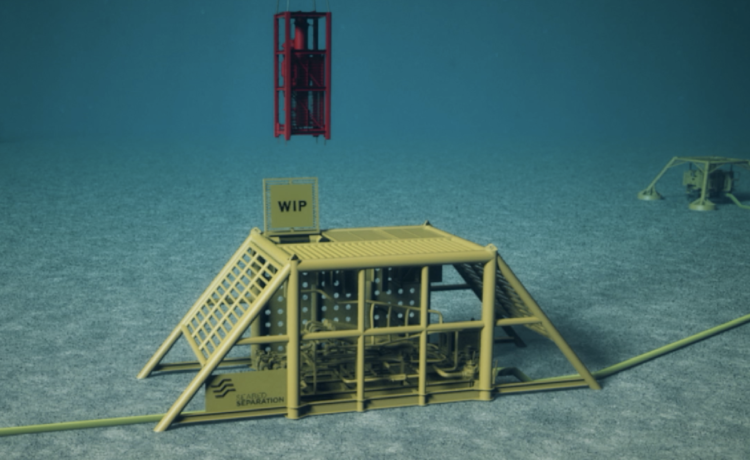

The Dual Pipe Separator (DPS) introduces new technology that makes oil separation more efficient. By removing and treating water locally, all transport from the well or field is for oil and gas only. This will reduce costs and increase revenues, by enabling increased oil recovery and accelerated production. This business effect will be especially significant subsea, where the DPS opens up for new production tie-ins on existing infrastructure.

Oil in Water quality

BS&W quality

Weight reduction and low footprint

| 15 000 BPD | |

| 30 000 BPD | |

| 60 000 BPD |

Liquid capacity per day

We focus on enabling IOR and accelerated production through;

Increased Oil Recovery

• We remove the water at the seabed and thus reduce the back pressure on the reservoir resulting in improved production

Accelerated Production

• We remove the water from the subsea infrastructure and thus we enable faster start-up of new wells and fields

• We enable production testing without production losses and with increased allocation accuracy

Sustainable development approach

• Smaller lighter with less steel and manufacturing and simpler installation process

• Lower power consumption to get the oil and gas to surface

Aker Solutions and Seabed Separation A/S has entered a technology cooperation agreement promoting a new subsea separation concept. The new concept named “The Dual Pipe Separator” (DPS) solves the challenges of high-cost field development, increasing water production and higher Environmental Sustainability Goals (ESG) requirements. Aker Solutions and Seabed Separation A/S have agreed to promote this technology […]

Read more

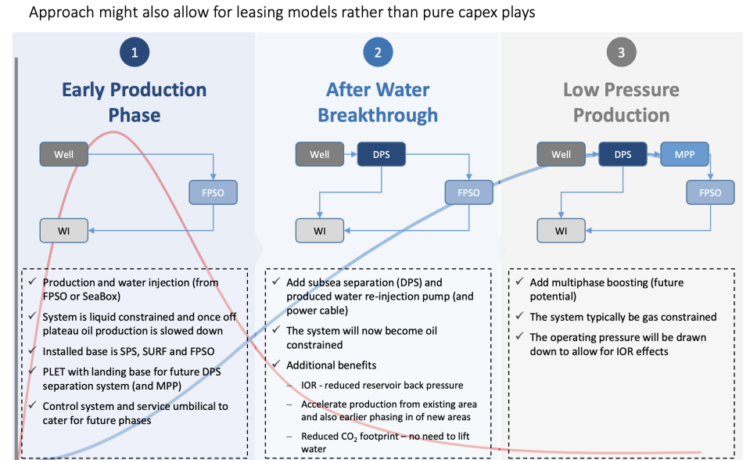

For an operator the key thing is to optimise the financial benefit from developing an oil & gas field. By phasing the development over the life of the field the operator will not only ensure optimum use of production solutions but also the financial benefit. For subsea development projects, tie-backs and larger standalone projects, our […]

Read more

Subsea separation has been in the making for the last 20 years after the initial pilot installations on Petrobras Marlim, Equinor Tordis and Troll Pilot, but not really been a viable option for field developers, before now. These initial subsea pilot installations where attempted marinating topside technologies for subsea application leading to oversized and overcomplicated […]

Read more

Nå skal de hente fram kalkulatoren for å bli en del av noe større. SINTEF sier at resultatene er svært lovende så langt.

Read more on tu.no

En tidligere Investinor-topp og en Høyre-backbencher fra Stortinget har funnet en lur måte å skille olje fra vann på. Nå skal de forhandle med de store gutta.

Read more

Det testes en ny metode for å separere olje og vann ved SINTEFs laboratorium i Trondheim. Heiner Schumann fra SINTEF forteller om prosessen.

Read more on tv.nrk.no

In the study the DPS was used to debottleneck an entire asset area by removing the water from one of the major infield pipelines and thus open for an early field development of a new discovery in the area

Read whole case

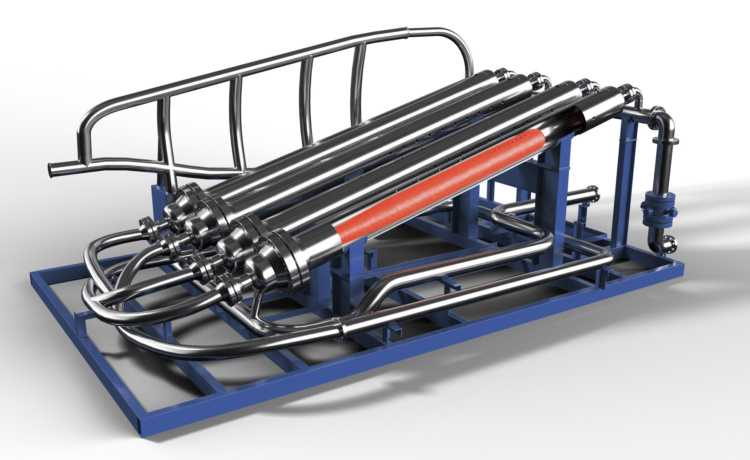

The DPS was modelled topside at a field centre to manage severe slugging and improve the liquid handling capacity. The DPS System was designed to be skid based and loaded on using the platform crane.

Read whole case

The DPS was designed to be a skid based debottlenecking tool on the FPSO topsides to make the FPSO more versatile to new business opportunities.

Read whole caseYou can adjust to the different phases of the life of an oil field. You can add, or remove modules to handle the different situations, like the build-up phase or decline phase. This is an major advantage.

Pump-free subsea boosting. The removal of produced water at the seabed has similar effect to a subsea booster pump with increasing effect as a function of increased water depth and water cut. The DPS could in some cases effectively boost production by 25-30 %, and increase asset valuation by as much as 100 % in the most extreme cases.